Garnet Abrasive For Blast Cleaning and Waterjet Cutting

Garnet Abrasive For Blast Cleaning and Waterjet Cutting

Garnet sand is made by grinding garnet as raw material. It has the characteristics of high hardness, high-temperature resistance, stable chemical properties, uniform particles, high grinding efficiency, and no scratches. It is suitable for the waterjet cutting industry; various metal, plastic, wood, and other surface sandblasting industries; super-precision grinding in machinery industry, precision casting, and grinding industry for kinescope glass bulbs, optical glass, silicon wafer, etc.

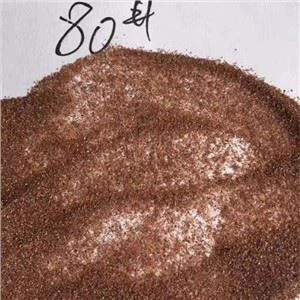

Recommendation: 60 mesh sand is used for cutting stainless steel, copper, and marble products. 80 mesh sand is used for cutting glass and ceramic products.

Because garnet has high hardness and good chemical properties, it is widely used in industrial production. The quality requirements of garnet are mainly hardness, purity, and particle size. The quality requirements are different for different purposes. Special purposes also have requirements for the particle size composition of the product, but there is no unified regulation, which is mainly negotiated by the supplier and the buyer. The use of garnets can be divided into garnets for abrasives and garnets for non-abrasives.

(1) Sandblasting and rust removal of steel structures, hulls, bridges, etc.;

(2) Waterjet cutting of metal, stone, glass, etc.;

(3) Filter media for chemical, petroleum, pharmaceutical, and water treatment;

(4) Grinding of marble, optical lens, glassware, leather, and other materials;

(5) Raw materials of grinding wheel, whetstone, emery cloth, and sandpaper;

(6) Wear-resistant materials such as highway pavement, airstrip, wear-resistant rubber, non-slip paint, etc.;

(7) Widely used in the field of the construction industry, high-grade real stone paint, exterior wall decoration, interior decoration, noble and elegant temperament. Ideal new non-metal wear-resistant floor aggregate.

Any doubt, contact with me.

----------------------------------------------------------

Annie Tian

International Dept Manager

Email: Annie_Tian@byabrasives.com

Whatsapp/Wechat: 86-15689023600

Hot Tags: garnet abrasive for blast cleaning and waterjet cutting, China garnet abrasive for blast cleaning and waterjet cutting suppliers, manufacturers, factory, Velcro Backed Sanding Discs, Black Silicon Carbide, Flexible Sanding Sponge, Aluminium Oxide Abrasives For Sandblasting, Wet Dry Film Sanding Discs, Wet dry sandpaper 1500

You Might Also Like

Send Inquiry