Glass Polishing Black Silicon Carbide Powder/Carborundum Powder

Our company's flap disc and grinding disc, Wet dry sanding discs, Automotive wet dry sandpaper has become a product trusted by the majority of users because of its good performance. With advanced technical support, we have won the affirmation of customers many times in the competitive market. At the same time, we are committed to developing foreign markets, and our products are highly praised by foreign users and friends. The company team is based on the people-oriented principle, fully armed with advanced culture, and the central task of the enterprise, seeking truth-seeking and pragmatic work. We have a proven track record of successfully exporting products to different countries. In order to adapt to the development needs of our company, to establish a good image of the company, to better meet the customers through the network to understand the company's products, to understand the company's services.

Silicon Carbide (SiC) is a compound of silicon and carbon. SiC is an excellent abrasive and was originally was used in producing grinding wheels and other various abrasive products. It is not only the lighest, but also the hardest ceramic material and has excellent thermal conductivity, low thermal expansion and is very resistant to acids and lyes. In addition to abrasive products, SiC is a high quality technical grade ceramic used in refractories, as an electrical conductor and numberous high-performance applications.

Black Silicon Carbide carborundum abrasives Properties

Typical Properties:

High Hardness, Abrasion Resistance;

High Thermal Conductivity;

High-Temperature Strength;

Low Thermal Expansion, Thermal Shock Resistance;

Chemical Inertness, Resistance to Chemical Reaction;

Ability to Function as a Semiconductor.

Black Silicon Carbide carborundum abrasives Grit

F grade series:

F14-F16-F20-F24-F30-F36-F46-F60-F80-F100-F120-F150-F180-F220-F240

P Grade series:

P14-P16-P20-P24-P30-P36-P46-P60-P80-P100-P120-P150-P180-P220-P240

Segment series:

0-1mm, 1-3mm, 3-5mm, 5-8mm, 0-3mm, 0-5mm, 0-10mm

Micro powder series:

320#-400#-500#-600#-800#-1000#-1200#-1500#-1800#-2000#-2500#-3000#-4000#-5000#-600#-8000#-9000#-10000#

W series:

W0.5, W1, W1.5, W2.5, W3.5, W5, W7, W10 , W14, W20, W28, W40, W63

Black Silicon Carbide carborundum abrasives Applications

Versatile and reliable

Typical Applications:

Bonded Abrasives - Grinding wheels etc. Coated Abrasives - Papers, Belts etc.

Blasting/Lapping/Polishing/Grinding/Milling; Sintered Parts, Hot-pressed Parts, Reaction Bonded Parts;

Ceramics, Ceramic Wear Parts; Refractories; Metallurgic - Steel Making;Diesel Particulate Filters;

Thermal Management, High Temp Sensors, Semiconductor; Metal Matrix Composites;

Wiresawing, Armor; Ultra High Purity SiC;

Aviation and aerospace series

Suitable for aircraft rotor turbine discs, turbine blades, aircraft landing gear support beams, aircraft wings, aircraft gear transmission parts, etc., which can strengthen the metal surface and increase the service life of the metal.

Digital Electronics Series

Suitable for sandblasting surface treatment of metal, plastic exterior and built-in products such as computers, mobile phones, cameras, tablets, etc., polishing the surfaces of various workpieces to make the surfaces more beautiful and smooth without reflecting light.

For some special-purpose workpieces, sandblasting can achieve different reflections or matte finishes at will.

Such as matte finish on the surface of stainless steel workpieces and plastic parts, round patterns on the surface of frosted glass, and burr processing on the surface of fabrics.

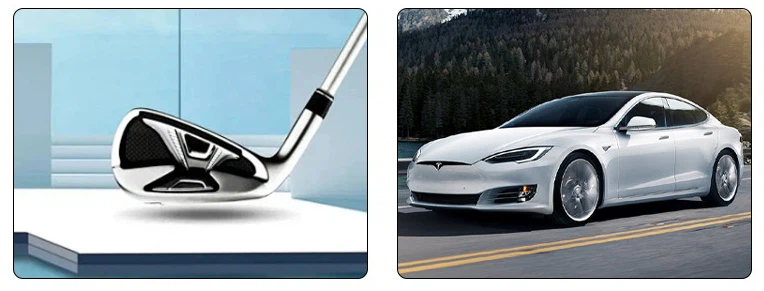

Golf and auto parts series

Suitable for golf heads and clubs, automotive aluminum alloy wheels, automotive cylinder liner inner wall, automotive aluminum alloy parts

, automotive gear internal parts, automotive transmission internal parts, with the functions of improving metal fatigue life and removing stress.

Mold and gear series

Suitable for glass molds, automobile molds, plastic molds, medical molds, mobile phone molds and automobile parts molds, etc., to clean dirt and excess glue and residues.

Hardware and electromechanical series

Suitable for hardware parts, hardware springs, electrical plug workpieces, motor housings and inner wall hardware mechanical teeth, hardware mechanical gears, electrical plug metal, and mechanical internal parts sandblasting.

Make the workpiece play the role of oil storage and surface strengthening.

Black Silicon Carbide Factory Showcase

Zibo Bingyang Abrasives Co., Ltd. is a professional manufacturer specializing in the production of high-quality coated abrasives, bonded abrasives, and various types of abrasive grains. With over 20 years of experience in abrasives manufacturing and marketing, we have established a strong reputation worldwide. Our comprehensive after-sales service ensures that our customers can rely on us without any concerns. Our products are highly regarded and have earned us a solid reputation globally.

We independently research and develop on the basis of introducing and digesting foreign advanced technology, constantly innovate and forge ahead, and strive to create a domestic first-class Glass Polishing Black Silicon Carbide Powder/Carborundum Powder brand. With the development of the economy, the globalization of the market, the customization of products and the specialization of business technologies, the competition has become more and more fierce. Our company has a superb R&D team, advanced testing equipment, perfect quality management system and good after-sales service.

You Might Also Like

Send Inquiry